Reorder Point Formula and Safety Stock: A Complete Guide

Content

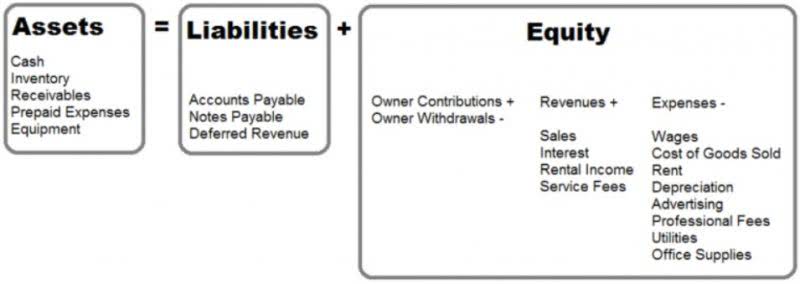

A reorder point is defined as the point or quantity of goods at which a company should reorder more products from their supplier or suppliers. An accurate reorder point will ensure that you never have to tap into your safety stock. When the greeting card company’s birthday card stock drops to 140 units, it’s time to reorder more stock. Lead time is how long it takes between when you order a product from a manufacturer and its delivery. The timing and planning of your lead time for purchases is important, especially for manufacturers.

- To account for this, the reorder point typically includes safety stock as a buffer.

- Businesses which follow lean inventory practices or a just-in-time management strategy usually don’t have safety stock.

- A modern inventory management system can bring greater efficiency to inventory processes through automation and digital tools.

- This inventory should not be reordered and you should offload it to make more room for profitable goods.

- But this doesn’t always work out for many businesses – think about an online auto parts store, for example.

A grocery store, for example, would likely have higher reorder points for quick-selling produce than a furniture store would for slow-selling mattresses. In this retailer’s guide to reorder points, you’ll learn everything you need to know to set effective reorder points and much more. Calculating and managing your reorder points can be difficult, especially if you’re using multiple spreadsheets to manage your inventory. Returning to our example, let’s say it takes one week for a birthday card order to arrive. However, it takes one day to get approval for the order and another day for the manufacturer to process the order.

Tips for setting reorder points

Shopify POS comes with tools to help you manage warehouse and store inventory in one place. Forecast demand, set reorder points and low stock alerts, create purchase orders, know which items are selling or sitting on shelves, count inventory, and more. The product of the lead time and average daily usage is also known as the lead time demand. You can call it a safety cushion to run your business peacefully. As the name suggests, it refers to storing excess items so that you can deal with an emergency or don’t have to run out of stock while facing some issue with the supply chain.

And let’s assume that the average daily use is 1.5 units, and the average lead time is 12 days. Average daily sales is the average number of units sold or used per day over a defined time period. A retailer would measure the average number of units sold, while a manufacturer would calculate the average number of components used per day. Reorder point calculationensures that you don’t fall behind on your next batch of inventory. With an accurate reorder point for each SKU, you’ll always have enough stock on hand to satisfy customer demand — without tying up excess capital in inventory.

Automate Your Reordering Process with Technology

This means you need to have an understanding of each product’s inventory levels and sales to optimize its reorder point. This is easily done using inventory management software that tracks everything you need to know about your inventory. Calculating the reorder point for a given product first requires that you determine a product’s average daily sales, lead time, and amount of safety stock. You can easily pull daily sales information from your POS system, online marketplace, or multichannel order management platform if you have any of these.

Now that you know the reorder point formula, we’ll show you how to find your reorder point by going through a sample calculation. Can’t you just wait until you’ve completely run out of inventory to reorder? Here’s why calculating and knowing your reorder point is important. There are a lot of memorable, one-off moments that are part of running a retail business. InFlow Cloud has a Reorder Stock window, which identifies which products need reordering, and creates new purchase orders with just one click.

Use A Spreadsheet To Calculate Reorder Point

Economic order quantity is the calculation used to determine how much to order. As you can see EOQ and ROP are very closely related, and are metrics that help prevent both https://www.bookstime.com/articles/real-estate-escrow overstocking, and shortages. “So many 3PLs have either bad or no front-facing software, making it impossible to keep track of what’s leaving or entering the warehouse.

The reorder point is key for business owners to determine how much safety stock a business should keep on hand as a buffer for excess demand. If you have at least one procurement cycle and one sales cycle worth of data, you can start using the reorder point formula to improve your inventory operations. Over those three months (or 92 days) that averages out to 1.5 units sold on average per day. Holding too much inventory ties up capital and eats into business profits with increased carrying costs.

Safety Stock and Reorder Point

It’s a small part of the advanced inventory management features in Fishbowl Manufacturing and Fishbowl Warehouse. Overstocking also means that you’re spending more than you need to to store extra inventory. When you know your reorder point, you can have just enough inventory on hand to meet customer demand, without overspending on safety stock or holding costs.

This simple calculator will help you pinpoint the critical stock level where you need to place your next order to minimise your chances of running out of stock. You need to order fresh stock before you run out of stock, but if it is too early you will reorder point formula calculator increase holding costs. If it is too late, you run the risk of stockouts, which may send your customers to the competition. Knowing the ROP benefits established businesses that have been selling products for years and new ones that are just starting.

All you have to do is calculate the reorder point for your inventory, input it into your POS, then turn low stock notifications on. With that in place, your POS will alert you when you’ve reached that point and need to place a new order. Automatic reorder notifications give you peace of mind, so you can spend less time checking inventory levels.

- Moreover, by analyzing the recorder point, you can reduce the risk of extra inventory.

- If yours is a small startup, calculating product reorder points is as simple as setting up an Excel spreadsheet (or a spreadsheet with Google Sheets or Apple Numbers).

- Supply-chain and shipping interruptions are all too common nowadays.

- Calculating it requires collecting the data on maximum and average daily usage and the lead time.

- Calculating ROP for each product can be time-consuming and challenging, especially if your inventory is patched together from several suppliers or you sell lots of products.

- That means that when your inventory falls to 62 lamps, it’s time to order more lamps.

Recommended Posts

février 16, 2023

Connect your Wave to Xero integration in 2 minutes

juillet 7, 2022